|

am2zzw00012612

DTC P2002:00 [SKYACTIV-D 1.5]

id0102q2150200

Details On DTCs

|

DESCRIPTION |

Diesel particulate filter function decreased |

|

|---|---|---|

|

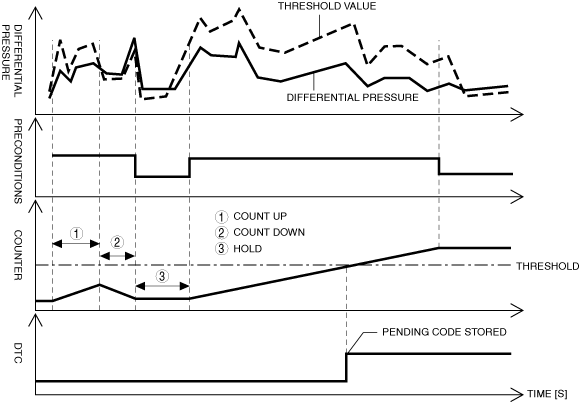

DETECTION CONDITION

|

Determination conditions

|

• The difference in the pressure before and after passing the diesel particulate filter of less than the specified value is detected for 2s.

|

|

Preconditions

|

• All of the following conditions are met for 2s:

|

|

|

Drive cycle

|

• 2

|

|

|

Self test type

|

• CMDTC self test

|

|

|

Sensor used

|

• Exhaust gas pressure sensor No.1

• Exhaust gas pressure sensor No.2 etc.

|

|

|

FAIL-SAFE FUNCTION

|

• Not applicable

|

|

|

VEHICLE STATUS WHEN DTCs ARE OUTPUT

|

• Check engine light is illuminated

|

|

|

POSSIBLE CAUSE

|

• Exhaust gas leakage from exhaust system

• Pipe between exhaust gas pressure sensor No.2 and catalytic converter (diesel particulate filter) restriction and/or damaged or improper routing

• Exhaust gas pressure sensor No.2 malfunction

• Exhaust gas pressure sensor No.1 malfunction

• Catalytic converter (diesel particulate filter) or diesel particulate filter malfunction (deformation, damage)

• PCM malfunction

|

|

System Wiring Diagram

Function Explanation (DTC Detection Outline)

am2zzw00012612

|

Repeatability Verification Procedure

PID Item/Simulation Item Used In Diagnosis

Function Inspection Using M-MDS

|

STEP |

INSPECTION |

ACTION |

|

|---|---|---|---|

|

1

|

PURPOSE: VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: IDENTIFY TRIGGER DTC FOR FREEZE FRAME DATA

• Is the DTC P2002:00 on FREEZE FRAME DATA?

|

Yes

|

Go to the next step.

|

|

No

|

Go to the troubleshooting procedure for DTC on FREEZE FRAME DATA.

(See DTC TABLE [SKYACTIV-D 1.5].)

|

||

|

3

|

PURPOSE: RECORD FREEZE FRAME DATA/SNAPSHOT DATA AND DIAGNOSTIC MONITORING TEST RESULTS TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the FREEZE FRAME DATA/snapshot data and DIAGNOSTIC MONITORING TEST RESULTS (misfire related) on the repair order.

|

—

|

Go to the next step.

|

|

4

|

PURPOSE: VERIFY RELATED PENDING CODE AND/OR DTC

• Switch the ignition off, then ON (engine off).

• Perform the Pending Trouble Code Access Procedure and DTC Reading Procedure.

• Are any other PENDING CODEs and/or DTCs present?

|

Yes

|

Go to the applicable PENDING CODE or DTC inspection.

(See DTC TABLE [SKYACTIV-D 1.5].)

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

|

No

|

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

||

Troubleshooting Diagnostic Procedure

Function Inspection Using M-MDS

|

STEP |

INSPECTION |

ACTION |

|

|---|---|---|---|

|

1

|

PURPOSE: INSPECT EXHAUST SYSTEM FOR LEAKAGE

• Visually inspect for exhaust gas leakage from the exhaust system.

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to Step 5.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: INSPECT EXHAUST GAS PRESSURE SENSOR NO.2 RELATED PIPE

• Visually inspect the exhaust gas pressure sensor No.2 related pipe for restriction and damaged.

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results, then go to Step 5.

|

|

No

|

Go to the next step.

|

||

|

3

|

PURPOSE: INSPECT EXHAUST GAS PRESSURE SENSOR NO.2

• Reconnect all disconnected connectors.

• Inspect the exhaust gas pressure sensor No.2.

• Is there any malfunction?

|

Yes

|

Replace the exhaust gas pressure sensor No.2, then go to Step 5.

|

|

No

|

Go to the next step.

|

||

|

4

|

PURPOSE: INSPECT EXHAUST GAS PRESSURE SENSOR NO.1

• Reconnect all disconnected connectors.

• Inspect the exhaust gas pressure sensor No.1.

• Is there any malfunction?

|

Yes

|

Replace the exhaust gas pressure sensor No.1, then go to the next step.

|

|

No

|

Catalytic converter (diesel particulate filter) or diesel particulate filter can be considered the cause.

• Replace the catalytic catalytic converter (diesel particulate filter), then go to the next step.

|

||

|

5

|

PURPOSE: PERFORM DTC INSPECTION AND VERIFY IF MALFUNCTIONING PART IS PCM

• Always reconnect all disconnected connectors.

• Clear the DTC from the PCM memory using the M-MDS.

• Implement the repeatability verification procedure.

• Perform the DTC Reading Procedure.

• Is the same DTC present?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM.

Go to the next step.

|

|

No

|

Go to the next step.

|

||

|

6

|

VERIFY AFTER REPAIR PROCEDURE

• Perform the “AFTER REPAIR PROCEDURE”.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

(See DTC TABLE [SKYACTIV-D 1.5].)

|

|

No

|

DTC troubleshooting completed.

|

||