REFRIGERANT CHARGING

id071000800400

-

Caution

-

• Do not use a different type of refrigerant or charge beyond the specified level. Otherwise, cooling ability will be lowered and the A/C compressor could be damaged.

-

Note

-

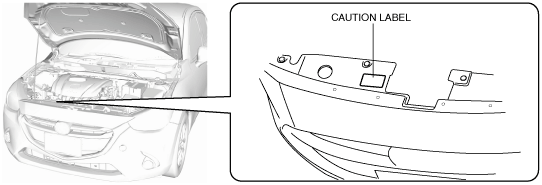

• The refrigerant used for the refrigerant system differs depending on the country. When draining or adding the refrigerant, verify the appropriate refrigerant type and specified amount of refrigerant from the caution label.

|

Engine type

|

Refrigerant type

|

Regular amount of refrigerant (approx. quantity) (g {oz})

|

|

SKYACTIV-G 1.3, SKYACTIV-G 1.5

|

HFC-134a (R-134a)

|

395—445 {14.0—15.6}

|

|

HFO-1234yf (R-1234yf)

|

335—385 {11.9—13.5}

|

|

SKYACTIV-D 1.5

|

HFC-134a (R-134a)

|

395—445 {14.0—15.6}

|

|

HFO-1234yf (R-1234yf)

|

365—415 {12.9—14.6}

|

Charging Recycled HFC-134a Refrigerant

1. Connect a HFC-134a recovery/recycling/recharging device to the vehicle and follow the device manufacturer’s instructions.

Charging Recycled HFO-1234yf Refrigerant

1. Connect a HFO-1234yf recovery/recycling/recharging device to the vehicle and follow the device manufacturer’s instructions.

Adding Compressor Oil

1. Weigh the compressor oil which is exhausted when collecting the refrigerant.

2. When adding refrigerant, add new compressor oil equivalent in weight to the exhausted amount to the refrigerant cycle.

Charging Preparation

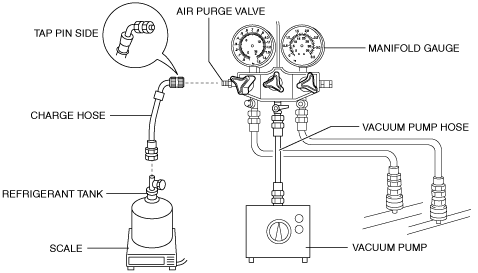

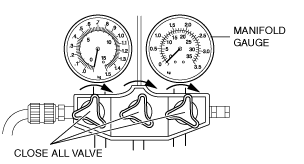

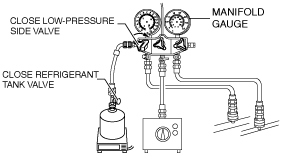

1. Close all the valves of the manifold gauge.

2. Close the valve of the refrigerant tank.

3. Install the manifold gauge set. (See REFRIGERANT SYSTEM GENERAL PROCEDURES.)

4. Connect the tap pin side of the charging hose to the air purge valve of the manifold gauge.

5. Connect the vacuum pump hose to the center joint of the manifold gauge.

6. Connect the vacuum pump hose to the vacuum pump.

7. Connect the charging hose to the refrigerant tank.

8. Place the refrigerant tank on the scale.

Evacuation

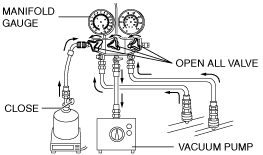

1. Open all the valves of the manifold gauge.

2. Start the vacuum pump and let it operate for 15 min.

3. Verify that high- and low-pressure side readings of the manifold gauge are at –101 kPa {–1.03 kgf/cm2, -14.6 psi}.

-

Caution

-

• If the manifold gauge valves are left open, vacuum pump oil will backflow into the refrigeration cycle and cause the cooling performance to lower. After stopping the vacuum pump, close the manifold gauge valves immediately.

4. Stop the vacuum pump and close all the valves of the manifold gauge.

5. Wait for 5 min after stopping the vacuum pump, and perform an airtightness check for the refrigerant system. (See Airtightness Check.)

Airtightness Check

1. Check the high- and low-pressure side readings of the manifold gauge.

-

Charging New Refrigerant

-

Warning

-

• If the refrigerant system is charged with a large amount of refrigerant when inspecting for gas leakage, and if any leakage should occur, the refrigerant will be released into the atmosphere. In order to prevent the accidental release of refrigerant which can destroy the ozone layer in the stratosphere, follow the proper procedures and charge with only a small amount of refrigerant when inspecting for gas leakage.

• If the engine is started while the valve on the high pressure side is open, highly pressurized refrigerant could backflow into the refrigerant tank and cause damage. Never start the engine while the valve on the high pressure side is open.

-

Caution

-

• If charging of refrigerant is started from the low pressure side, the A/C compressor vanes will not expand outward and an abnormal sound may be heard. Always start the refrigerant charging from the high pressure side.

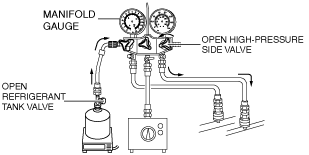

1. Open the valve of the refrigerant tank.

2. Weigh the refrigerant tank to charge the suitable amount of refrigerant.

3. Open the high-pressure side valve of the manifold gauge.

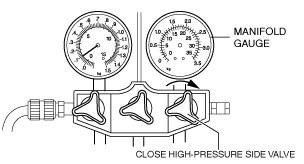

4. When the low-pressure side reading increases to 0.098 MPa {1.0 kgf/cm2, 14 psi}, close the high-pressure side valve of the manifold gauge.

5. Inspect for gas leakage from the piping connection using a gas leak detector or a fluorescent agent-detecting UV black light.

-

• If there is no leakage, go to Step 7.

• If leakage is found at a loose joint, tighten the joint, then go to next step.

6. Inspect for leakage again.

-

• If there is no leakage after tightening the joint, go to next step.

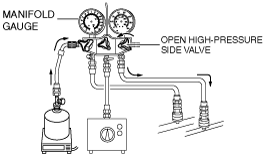

7. Open the high-pressure side valve of the manifold gauge and charge with refrigerant until the weight of refrigerant tank has decreased 250 g {8.82 oz} from the amount in Step2.

8. Close the high-pressure side valve of the manifold gauge.

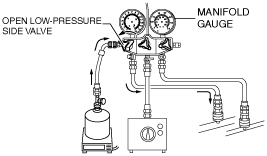

9. Start the engine and actuate the A/C compressor.

-

Warning

-

• If the valve on the high pressure side is opened while the engine is running, highly pressurized refrigerant could backflow into the refrigerant tank and cause damage. Never open the valve on the high pressure side while the engine is running.

10. Open the low-pressure side valve of the manifold gauge and charge with refrigerant until the weight of the refrigerant tank has decreased to the regular amount from the amount in Step 2.

-

Warning

-

• If the refrigerant system is charged with the refrigerant tank upside down, liquid refrigerant will be charged into the system, and the A/C compressor could become highly pressurized and damaged. Never charge refrigerant with the refrigerant tank upside down.

11. Close the low-pressure side valve of the manifold gauge and the valve of the refrigerant tank.

12. Stop the engine and A/C compressor.

13. Perform the leak test. (See Leak Test.)

Leak Test

-

Caution

-

• Looking directly at a fluorescent agent-detecting UV black light may cause injury to the eyes. Do not look directly into the light of a fluorescent agent-detecting UV black light.

-

Note

-

• Because fluorescent agents (yellow or light green dye) are in the refrigeration cycle, the leak test can be performed with a fluorescent agent-detecting UV black light.

1. Inspect for gas leakage from the piping connection using a gas leak detector or a fluorescent agent-detecting UV black light.

-

• If there is no leakage, go to Step 3.

• If leakage is found at a loose joint, tighten the joint, then go to the next step.

2. Inspect for leakage again.

-

• If there is no refrigerant leakage, perform the procedure from the vacuum pump operation again. (See

Evacuation.)

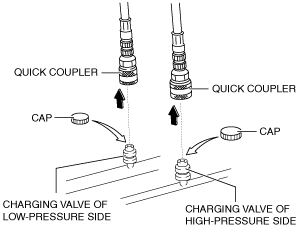

3. Disconnect the quick couplers from the charging valves.

4. Install the caps to the charging valves.