|

DTC P0A94:00 [SKYACTIV-D 1.5]

id0102q2004400

Details On DTCs (Without i-ELOOP)

|

DESCRIPTION |

DC-DC converter: control circuit signal error |

|

|---|---|---|

|

DETECTION CONDITION

|

Determination conditions

|

• Internal malfunction signal from DC-DC converter via BCM is received. (CAN/LIN communication).

• Input signal from the DC-DC converter limits the pressure increase time.

• Input signal from the DC-DC converter does not implement pressure increase after a pressure increase command to the DC-DC converter.

|

|

Preconditions

|

• Not applicable

|

|

|

Drive cycle

|

• 1

|

|

|

Self test type

|

• CMDTC self test

|

|

|

Sensor used

|

• Not applicable

|

|

|

FAIL-SAFE FUNCTION

|

• Not applicable

|

|

|

VEHICLE STATUS WHEN DTCs ARE OUTPUT

|

• Flashes i-stop warning light (amber).

|

|

|

POSSIBLE CAUSE

|

• DC-DC converter connector or terminals malfunction

• Short to ground or open circuit in DC-DC converter power supply circuit

• PCM connector or terminals malfunction

• Short to ground in wiring harness between DC-DC converter terminal F and PCM terminal 2P

• Short to power supply in wiring harness between DC-DC converter terminal F and PCM terminal 2P

• Open circuit in wiring harness between DC-DC converter terminal F and PCM terminal 2P

• Battery malfunction

• DC-DC converter malfunction

• BCM malfunction

• PCM malfunction

|

|

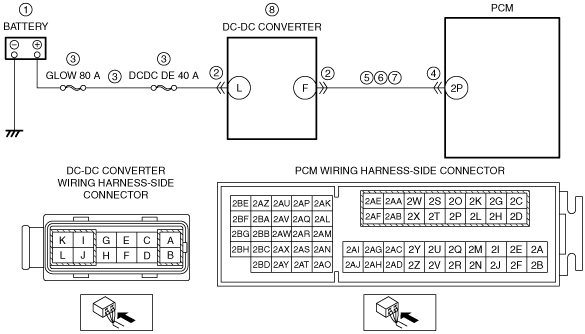

System Wiring Diagram (Without i-ELOOP)

am2zzw00012484

|

Function Explanation (DTC Detection Outline) (Without i-ELOOP)

Repeatability Verification Procedure (Without i-ELOOP)

PID Item/Simulation Item Used In Diagnosis (Without i-ELOOP)

Function Inspection Using M-MDS (Without i-ELOOP)

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

PURPOSE: VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: VERIFY IF BATTERY VOLTAGE IS FALSELY RECOGNIZED BY DTC RELATED CAN OR LIN COMMUNICATION

• Switch the ignition off, then ON (engine off).

• Perform the PCM and BCM DTC inspection using the M-MDS.

(See DTC INSPECTION [BCM].)

• Are DTCs related CAN or LIN communication recorded?

|

Yes

|

Repair or replace the malfunctioning part according to the applicable DTC troubleshooting.

(See DTC TABLE [SKYACTIV-D 1.5].)

(See DTC TABLE [BCM].)

Go to the next step.

|

|

No

|

Go to the next step.

|

||

|

3

|

PURPOSE: VERIFY IF THE CURRENT SENSOR IS MISIDENTIFYING MALFUNCTIONS DUE TO A BCM MALFUNCTION

• Perform the BCM DTC inspection using the M-MDS.

(See DTC INSPECTION [BCM].)

• Are any DTCs present?

|

Yes

|

Repair or replace the malfunctioning part according to the applicable DTC troubleshooting.

(See DTC TABLE [BCM].)

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

|

No

|

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

Troubleshooting Diagnostic Procedure (Without i-ELOOP)

Diagnostic Procedure

|

STEP |

INSPECTION |

ACTION |

|

|---|---|---|---|

|

1

|

PURPOSE: INSPECT BATTERY

• Switch the ignition off.

• Inspect the battery.

(See BATTERY INSPECTION.)

• Is there any malfunction?

|

Yes

|

Recharge or replace the battery, then go to Step 8.

(See BATTERY RECHARGING.)

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: INSPECT DC-DC CONVERTER CONNECTOR CONDITION

• Switch the ignition off.

• Disconnect the DC-DC converter connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 8.

|

|

No

|

Go to the next step.

|

||

|

3

|

PURPOSE: INSPECT DC-DC CONVERTER POWER SUPPLY CIRCUIT FOR SHORT TO GROUND OR OPEN CIRCUIT

• Verify that the DC-DC converter connector is disconnected.

• Measure the voltage at the DC-DC converter terminal L (wiring harness-side).

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect the GLOW 80 A fuse and DCDC DE 40 A fuse.

• If the fuse is blown:

• If the fuse is damaged:

• If all fuses are normal:

Go to Step 8.

|

||

|

4

|

PURPOSE: INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 8.

|

|

No

|

Go to the next step.

|

||

|

5

|

PURPOSE: INSPECT DC-DC CONVERTER SIGNAL CIRCUIT FOR SHORT TO GROUND

• Verify that the DC-DC converter and PCM connectors are disconnected.

• Inspect for continuity between DC-DC converter terminal F (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between DC-DC converter terminal F and PCM terminal 2P.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to ground.

Go to Step 8.

|

|

No

|

Go to the next step.

|

||

|

6

|

PURPOSE: INSPECT DC-DC CONVERTER SIGNAL CIRCUIT FOR SHORT TO POWER SUPPLY

• Verify that the DC-DC converter and PCM connectors are disconnected.

• Switch the ignition ON (engine off).

• Measure the voltage at the DC-DC converter terminal F (wiring harness-side).

• Is the voltage 0 V?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between DC-DC converter terminal F and PCM terminal 2P.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to power supply.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to power supply.

Go to Step 8.

|

||

|

7

|

PURPOSE: INSPECT DC-DC CONVERTER SIGNAL CIRCUIT FOR OPEN CIRCUIT

• Verify that the DC-DC converter and PCM connectors are disconnected.

• Switch the ignition off.

• Inspect for continuity between DC-DC converter terminal F (wiring harness-side) and PCM terminal 2P (wiring harness-side).

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between DC-DC converter terminal F and PCM terminal 2P.

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to the next step.

|

||

|

8

|

PURPOSE: VERIFY DTC TROUBLESHOOTING COMPLETED

• Always reconnect all disconnected connectors.

• Clear the DTC from the PCM memory using the M-MDS.

• Implement the repeatability verification procedure.

• Perform the DTC Reading Procedure.

• Is the same DTC present?

|

Yes

|

Replace the DC-DC converter, and then perform Step 8 again.

• If the malfunction recurs, replace the PCM.

Go to the next step.

|

|

No

|

Go to the next step.

|

||

|

9

|

PURPOSE: VERIFY AFTER REPAIR PROCEDURE

• Perform the “AFTER REPAIR PROCEDURE”.

• Are any DTCs present?

|

Yes

|

Go to the applicable DTC inspection.

(See DTC TABLE [SKYACTIV-D 1.5].)

|

|

No

|

DTC troubleshooting completed.

|

||

Details On DTCs (With i-ELOOP)

|

DESCRIPTION |

DC-DC converter (i-ELOOP): control circuit signal error |

|

|---|---|---|

|

DETECTION CONDITION

|

Determination conditions

|

• Internal malfunction signal from DC-DC converter (i-ELOOP) is received.

• Condition in which DC-DC converter (i-ELOOP) output voltage, based on demand voltage of PCM, is low continues.

• Condition in which the PCM receives a relay operation command signal from the DC-DC converter (i-ELOOP) which differs from the relay operation signal sent from the DC-DC converter (i-ELOOP). Or the signal itself is not received.

• Condition in which DC-DC converter (i-ELOOP) 4A terminal current value of 30 A or more continues.

|

|

Preconditions

|

• Not applicable

|

|

|

Drive cycle

|

• 1

|

|

|

Self test type

|

• CMDTC self test

|

|

|

Sensor used

|

• Not applicable

|

|

|

FAIL-SAFE FUNCTION

|

• Not applicable

|

|

|

VEHICLE STATUS WHEN DTCs ARE OUTPUT

|

• Flashes i-stop warning light (amber).

• The following vehicle conditions differ depending on the type of malfunction

|

|

|

POSSIBLE CAUSE

|

• Short to ground in wiring harness between the following terminals:

• Open circuit in wiring harness between the following terminals:

• Connector or terminal malfunction of the following parts:

• High-power load, non-genuine part installed to line connected to DC-DC converter (i-ELOOP) terminal 4A

• DC-DC converter (i-ELOOP) malfunction (DTC U3000:49 may be detected simultaneously)

• PCM malfunction

|

|

System Wiring Diagram (With i-ELOOP)

am2zzw00012485

|

Function Explanation (DTC Detection Outline) (With i-ELOOP)

Repeatability Verification Procedure (With i-ELOOP)

PID Item/Simulation Item Used In Diagnosis (With i-ELOOP)

Function Inspection Using M-MDS (With i-ELOOP)

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

PURPOSE: VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: VERIFY IF POWER SUPPLY IS AFFECTED BY DTC RELATED TO DC-DC CONVERTER (i-ELOOP)

• Switch the ignition off, then ON (engine off).

• Perform the DC-DC converter (i-ELOOP) DTC inspection using the M-MDS.

(See DTC INSPECTION [i-ELOOP].)

• Is the P0A12:00 or U3000:49 present?

|

Yes

|

Go to the applicable DTC inspection.

(See DTC P0A12:00 [i-ELOOP].)

(See DTC U3000:49 [i-ELOOP].)

Go to the next step.

|

|

No

|

Go to the next step.

|

||

|

3

|

PURPOSE: DETERMINE IF MALFUNCTION CAUSED BY DC-DC CONVERTER (i-ELOOP)

• Start the engine.

• Is illuminate the master warning light?

|

Yes

|

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

|

No

|

Go to the next step.

|

||

|

4

|

PURPOSE: DETERMINE IF MALFUNCTION CAUSED BY DC-DC CONVERTER (i-ELOOP)

• Is the charging system warning light illuminated after the engine is restarted by i-stop, or is there an abnormality in the navigation/audio unit behavior?

|

Yes

|

Go to the troubleshooting procedure to perform the procedure from Step 3.

|

|

No

|

Go to the troubleshooting procedure to perform the procedure from Step 5.

|

Troubleshooting Diagnostic Procedure (With i-ELOOP)

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

PURPOSE: VERIFY IF SHORT TO GROUND IN EACH WIRING HARNESS AFFECTS DIAGNOSTIC RESULTS

• Switch the ignition off.

• Remove the service plug.

• Disconnect the connector of the following parts.

• Inspect for continuity between the following terminals (wiring harness-side) and body ground:

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• PCM terminal 2AU—DC-DC converter (i-ELOOP) terminal 1D

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to ground.

Go to Step 7.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: VERIFY IF OPEN CIRCUIT IN EACH WIRING HARNESS AFFECTS DIAGNOSTIC RESULTS

• Verify that the DC-DC converter (i-ELOOP) and PCM connectors are disconnected.

• Inspect for continuity between the following terminals (wiring harness-side):

• Is there continuity?

|

Yes

|

Replace the DC-DC converter (i-ELOOP).

Go to Step 7.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• PCM terminal 2AU—DC-DC converter (i-ELOOP) terminal 1D

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step 7.

|

||

|

3

|

PURPOSE: VERIFY IF SHORT TO GROUND IN EACH WIRING HARNESS AFFECTS DIAGNOSTIC RESULTS

• Switch the ignition off.

• Remove the service plug.

• Disconnect the connector of the following parts.

• Inspect for continuity between the following terminals (wiring harness-side) and body ground:

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• PCM terminal 2P—DC-DC converter (i-ELOOP) terminal 1L

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to ground.

Go to Step 7.

|

|

No

|

Go to the next step.

|

||

|

4

|

PURPOSE: VERIFY IF OPEN CIRCUIT IN EACH WIRING HARNESS AFFECTS DIAGNOSTIC RESULTS

• Verify that the DC-DC converter (i-ELOOP) and PCM connectors are disconnected.

• Inspect for continuity between the following terminals (wiring harness-side):

• Is there continuity?

|

Yes

|

Replace the DC-DC converter (i-ELOOP).

Go to Step 7.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• PCM terminal 2P—DC-DC converter (i-ELOOP) terminal 1L

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step 7.

|

||

|

5

|

PURPOSE: VERIFY IF MALFUNCTION OCCURRING IS CAUSED BY WIRING HARNESS/CONNECTOR LOSS

• Have all the wiring harnesses/connectors which can be considered the cause of DTC P0A94:00 been inspected?

|

Yes

|

Go to the next step.

|

|

No

|

Inspect all the related wiring harnesses/connectors.

• If there is a malfunction

• If there is no malfunction

|

||

|

6

|

PURPOSE: VERIFY DC-DC CONVERTER (i-ELOOP) REPLACEMENT RECORD

• Is the DC-DC converter (i-ELOOP) being replaced within the troubleshooting diagnostic procedure this time?

|

Yes

|

Replace the PCM.

Go to the next step.

|

|

No

|

Replace the DC-DC converter (i-ELOOP).

Go to the next step.

|

||

|

7

|

PURPOSE: VERIFICATION OF VEHICLE REPAIR COMPLETION

• Always reconnect all disconnected connectors.

• Reinstall the service plug.

• Clear the DTC from the PCM memory using the M-MDS.

• Implement the repeatability verification procedure.

• Perform the DTC Reading Procedure.

• Is the same DTC present?

|

Yes

|

Repeat the inspection from Step 5.

|

|

No

|

Go to the next step.

|

||

|

8

|

PURPOSE: VERIFY IF THERE IS ANY OTHER MALFUNCTION

• Is any other DTC or pending code stored?

|

Yes

|

Go to the applicable DTC inspection.

(See DTC TABLE [SKYACTIV-D 1.5].)

|

|

No

|

DTC troubleshooting completed.

|