|

1

|

PERFORM INSTRUMENT CLUSTER DTC INSPECTION

• Are any DTCs present?

|

Yes

|

Perform the applicable DTC inspection. (See DTC TABLE [INSTRUMENT CLUSTER].) |

|

No

|

Go to the next step.

|

|

2

|

INSPECT SAS CONTROL MODULE CONNECTOR

-

Warning

-

• Handling the component parts improperly can accidentally operate (deploy) the air bag module, which may seriously injure you. Read the service warnings/cautions and the workshop manual before handling the air bag system components.

• Switch the ignition off.

• Disconnect the negative battery cable and wait for 1 min or more.

• Inspect the SAS control module connector terminal for poor connection (such as damaged/pulled-out pins, and corrosion).

• Is there any malfunction?

|

Yes

|

Replace the malfunctioning part, then go to the next step.

|

|

No

|

Go to the next step.

|

|

3

|

INSPECT INSTRUMENT CLUSTER CONNECTOR

• Inspect the instrument cluster terminal for poor connection (such as damaged/pulled-out pins, and corrosion).

• Is there any malfunction?

|

Yes

|

Replace the malfunctioning part, then go to Step 7.

|

|

No

|

Go to the next step.

|

|

4

|

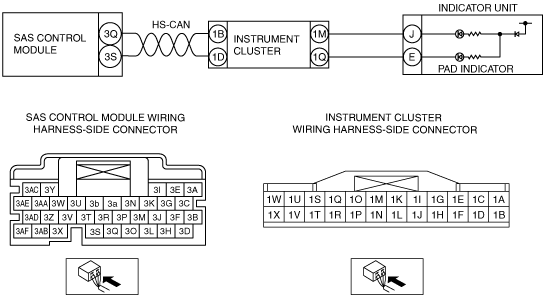

INSPECT SAS CONTROL MODULE CIRCUIT FOR SHORT TO GROUND

• Instrument cluster and SAS control module connectors are disconnected.

• Inspect for continuity between the following terminals (wiring harness-side) and body ground:

-

― SAS control module terminal 3Q

― SAS control module terminal 3S

-

Note

-

• Inspect for continuity while shaking the wiring harness between the SAS control module and instrument cluster.

• Is there continuity?

|

Yes

|

Replace the wiring harness for a possible short to ground, then go to Step 7.

|

|

No

|

Go to the next step.

|

|

5

|

INSPECT SAS CONTROL MODULE CIRCUIT FOR OPEN CIRCUIT

• Instrument cluster and SAS control module connectors are disconnected.

• Inspect for continuity between the following terminals (wiring harness-side):

-

― Instrument cluster terminal 1B—SAS control module terminal 3Q

― Instrument cluster terminal 1D—SAS control module terminal 3S

-

Note

-

• Inspect for continuity while shaking the wiring harness between the SAS control module and instrument cluster.

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the wiring harness for a possible open circuit, then go to Step 7.

|

|

6

|

INSPECT SAS CONTROL MODULE CIRCUIT FOR SHORT TO POWER SUPPLY

• Instrument cluster and SAS control module connectors are disconnected.

• Switch the ignition ON (engine off or on).

• Measure the voltage at the following terminals (wiring harness-side):

-

― SAS control module terminal 3Q

― SAS control module terminal 3S

-

Note

-

• Measure the voltage while shaking the wiring harness between the SAS control module and instrument cluster.

• Is the voltage 0V?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the wiring harness for a possible short to power supply, then go to the next step.

|

|

7

|

PERFORM SAS CONTROL MODULE DTC INSPECTION

• Switch the ignition to off.

• Disconnect the negative battery cable and wait for 1min or more.

• Connect the SAS control module connectors.

• Reconnect all disconnected connectors.

• Switch the ignition ON (engine off or on).

• Are the same DTCs present?

|

Yes

|

|

|

No

|

DTC troubleshooting completed.

|