|

DTC P0011:00, P0012:00 [SKYACTIV-G 1.3, SKYACTIV-G 1.5]

id0102q1710100

Details On DTCs (SKYACTIV-G 1.5 (with 4-2-1 exhaust system))

|

DESCRIPTION |

Electric variable valve timing control system: • P0011:00: Over-advanced

• P0012:00: Over-retarded

|

|

|---|---|---|

|

DETECTION CONDITION

|

Determination conditions

|

• P0011:00: For the advance amount from the maximum intake valve retard position, a condition in which the actual advance amount is larger than the target value continues for a specified period of time.

|

|

• P0012:00: For the advance amount from the maximum intake valve retard position, a condition in which the actual advance amount is smaller than the target value continues for a specified period of time.

|

||

|

Preconditions

|

• Battery voltage: above 11 V*1

• Engine speed: 5,000 rpm or less*1

• Engine coolant temperature: 20 °C {68 °F} or more*1

• The following DTCs are not detected:

*1: Value can be verified by displaying PIDs using M-MDS

|

|

|

Malfunction determination period

|

• 10 s period

|

|

|

Drive cycle

|

• 1

|

|

|

Self test type

|

• CMDTC self test

|

|

|

Sensor used

|

• CKP sensor

• Intake CMP sensor

|

|

|

FAIL-SAFE FUNCTION

|

• Not applicable

|

|

|

VEHICLE STATUS WHEN DTCs ARE OUTPUT

|

• Illuminates check engine light.

|

|

|

POSSIBLE CAUSE

|

• Electric variable valve timing motor/driver connectors or terminals malfunction

• Short to ground or open circuit in electric variable valve timing relay power supply circuit (without i-ELOOP)

• Short to ground or open circuit in electric variable valve timing relay power supply circuit (with i-ELOOP)

• Short to ground in wiring harness between the following terminals:

• Open circuit in wiring harness between the following terminals:

• PCM connector or terminals malfunction

• Electric variable valve timing relay malfunction

• Electric variable valve timing motor malfunction

• Electric variable valve timing actuator malfunction

• Timing chain malfunction

• Mis-detection of intake CMP sensor

• Mis-detection of CKP sensor

• PCM malfunction

|

|

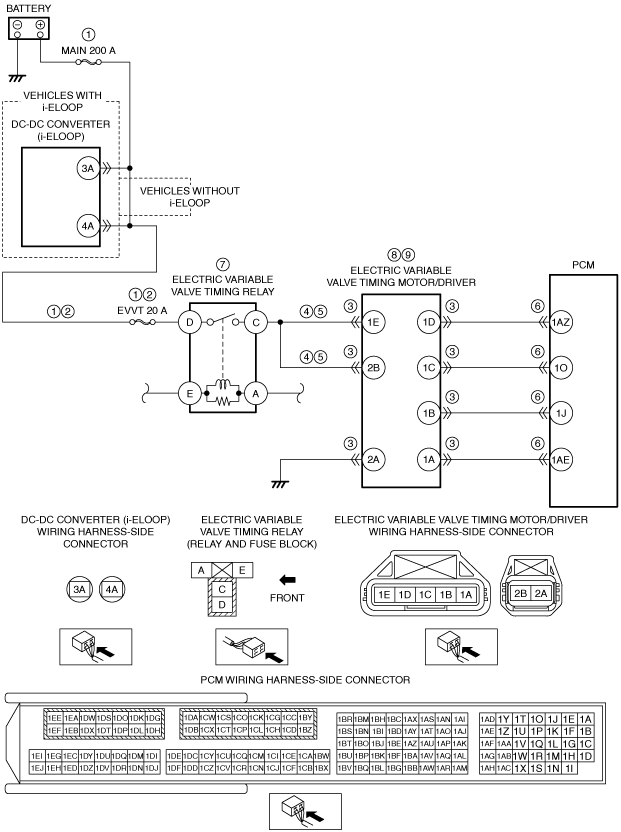

System Wiring Diagram (SKYACTIV-G 1.5 (with 4-2-1 exhaust system))

am2zzw00010493

|

Function Explanation (DTC Detection Outline) (SKYACTIV-G 1.5 (with 4-2-1 exhaust system))

am6zzw00011803

|

am3zzw00014488

|

Repeatability Verification Procedure (SKYACTIV-G 1.5 (with 4-2-1 exhaust system))

PID Item/Simulation Item Used In Diagnosis (SKYACTIV-G 1.5 (with 4-2-1 exhaust system))

PID/DATA monitor item table

|

Item |

Definition |

Unit |

Condition/Specification |

|---|---|---|---|

|

VT_IN_ACT

|

Actual exhaust variable valve timing control - Retard amount from max advance position

|

°

|

• Displays actual exhaust variable valve timing - Retard amount from max advance position

Idle (after warm up)

Racing (engine speed is 2,000 rpm)

|

|

VT_IN_DES

|

Target exhaust variable valve timing control - Retard amount from max advance position

|

°

|

• Displays target exhaust variable valve timing - Retard amount from max advance position

Idle (after warm up)

Racing (engine speed is 2,000 rpm)

|

Function Inspection Using M-MDS (SKYACTIV-G 1.5 (with 4-2-1 exhaust system))

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

PURPOSE: VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: RECORD VEHICLE STATUS AT TIME OF DTC DETECTION TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the FREEZE FRAME DATA/snapshot data on the repair order.

|

—

|

Go to the next step.

|

|

3

|

PURPOSE: VERIFY IF DIAGNOSTIC RESULT IS AFFECTED BY OTHER RELATED DTCs OCCURRING

• Switch the ignition off, then ON (engine off).

• Perform the Pending Trouble Code Access Procedure and DTC Reading Procedure.

• Is the PENDING CODE/DTC P0010:00, P0335:00, P0340:00 or P1380:00 also present?

|

Yes

|

Go to the applicable DTC inspection.

Go to the next step.

|

|

No

|

Go to the next step.

|

||

|

4

|

PURPOSE: VERIFY CONFORMITY OF ACTUAL INTAKE VALVE TIMING

• Start the engine and idle it.

• Access the following PIDs using the M-MDS:

• Perform the following:

• Does the monitor value of the PID item VT_IN_ACT conform to the VT_IN_DES PID value?

|

Yes

|

Go to the next step.

|

|

No

|

Vehicles with i-ELOOP:

• Go to the troubleshooting procedure to perform the procedure from Step 2.

Vehicles without i-ELOOP:

• Go to the troubleshooting procedure to perform the procedure from Step 1.

|

||

|

5

|

PURPOSE: VERIFY CONNECTOR CONNECTIONS

• Start the engine.

• Access the VT_IN_ACT PID using the M-MDS.

• Does the PID value fluctuate when the following connectors are shaken?

|

Yes

|

Repair or replace the applicable wiring harness or connector parts.

Go to the troubleshooting procedure to perform the procedure from Step 13.

|

|

No

|

Vehicles with i-ELOOP:

• Go to the troubleshooting procedure to perform the procedure from Step 2.

Vehicles without i-ELOOP:

• Go to the troubleshooting procedure to perform the procedure from Step 1.

|

Troubleshooting Diagnostic Procedure (SKYACTIV-G 1.5 (with 4-2-1 exhaust system))

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

PURPOSE: INSPECT ELECTRIC VARIABLE VALVE TIMING RELAY POWER SUPPLY CIRCUIT FOR SHORT TO GROUND OR OPEN CIRCUIT

• Switch the ignition off.

• Remove the electric variable valve timing relay.

(See RELAY LOCATION.)

• Measure the voltage at the electric variable valve timing relay terminal D (wiring harness-side).

• Is the voltage B+?

|

Yes

|

Go to Step 3.

|

|

No

|

Inspect the MAIN 200 A fuse and EVVT 20 A fuse.

• If the fuse is blown:

• If the fuse is damaged:

• If all fuses are normal:

Go to Step 13.

|

||

|

2

|

PURPOSE: INSPECT ELECTRIC VARIABLE VALVE TIMING RELAY POWER SUPPLY CIRCUIT FOR SHORT TO GROUND OR OPEN CIRCUIT

• Switch the ignition off.

• Remove the electric variable valve timing relay.

(See RELAY LOCATION.)

• Measure the voltage at the electric variable valve timing relay terminal D (wiring harness-side).

• Is the voltage B+?

|

Yes

|

Go to the next step.

|

|

No

|

Remove the service plug.

Inspect the EVVT 20 A fuse.

• If the fuse is blown:

• If the fuse is damaged:

• If the fuse is normal:

Reinstall the service plug.

Go to Step 13.

|

||

|

3

|

PURPOSE: INSPECT ELECTRIC VARIABLE VALVE TIMING MOTOR/DRIVER CONNECTOR CONDITION

• Disconnect the electric variable valve timing motor/driver connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 13.

|

|

No

|

Go to the next step.

|

||

|

4

|

PURPOSE: INSPECT ELECTRIC VARIABLE VALVE TIMING RELAY CONTROL CIRCUIT FOR SHORT TO GROUND

• Electric variable valve timing relay is removed.

• Verify that the electric variable valve timing motor/driver connector is disconnected.

• Inspect for continuity between electric variable valve timing relay terminal C (wiring harness-side) and body ground.

• Is there continuity?

|

Yes

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Electric variable valve timing relay terminal C—Electric variable valve timing motor/driver terminal 1E

• Electric variable valve timing relay terminal C—Electric variable valve timing motor/driver terminal 2B

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for a short to ground.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has a short to ground.

Go to Step 13.

|

|

No

|

Go to the next step.

|

||

|

5

|

PURPOSE: INSPECT ELECTRIC VARIABLE VALVE TIMING RELAY CONTROL CIRCUIT FOR OPEN CIRCUIT

• Electric variable valve timing relay is removed.

• Verify that the electric variable valve timing motor/driver connector is disconnected.

• Inspect for continuity between the following terminals (wiring harness-side):

• Is there continuity?

|

Yes

|

Go to the next step.

|

|

No

|

Refer to the wiring diagram and verify whether or not there is a common connector between the following terminals:

• Electric variable valve timing relay terminal C—Electric variable valve timing motor/driver terminal 1E

• Electric variable valve timing relay terminal C—Electric variable valve timing motor/driver terminal 2B

If there is a common connector:

• Determine the malfunctioning part by inspecting the common connector and the terminal for corrosion, damage, or pin disconnection, and the common wiring harness for an open circuit.

• Repair or replace the malfunctioning part.

If there is no common connector:

• Repair or replace the wiring harness which has an open circuit.

Go to Step 13.

|

||

|

6

|

PURPOSE: INSPECT PCM CONNECTOR CONDITION

• Disconnect the PCM connector.

• Inspect for poor connection (such as damaged/pulled-out pins, corrosion).

• Is there any malfunction?

|

Yes

|

Repair or replace the connector and/or terminals, then go to Step 13.

|

|

No

|

Go to the next step.

|

||

|

7

|

PURPOSE: DETERMINE INTEGRITY OF ELECTRIC VARIABLE VALVE TIMING RELAY

• Inspect the electric variable valve timing relay.

(See RELAY INSPECTION.)

• Is there any malfunction?

|

Yes

|

Replace the electric variable valve timing relay, then go to Step 13.

|

|

No

|

Go to the next step.

|

||

|

8

|

PURPOSE: DETERMINE INTEGRITY OF ELECTRIC VARIABLE VALVE TIMING MOTOR

• Inspect the electric variable valve timing motor.

• Is there any malfunction?

|

Yes

|

Replace the electric variable valve timing motor/driver, then go to Step 13.

|

|

No

|

Go to the next step.

|

||

|

9

|

PURPOSE: DETERMINE INTEGRITY OF ELECTRIC VARIABLE VALVE TIMING ACTUATOR

• Inspect the electric variable valve timing actuator.

• Is there any malfunction?

|

Yes

|

Replace the electric variable valve timing actuator, then go to Step 13.

|

|

No

|

Go to the next step.

|

||

|

10

|

PURPOSE: VERIFY ASSEMBLY CONDITION OF TIMING CHAIN

• Verify the condition of the timing chain assembly (intake valve timing, looseness, jumping).

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning part.

Assemble the timing chain using the correct timing, then go to Step 13.

|

|

No

|

Go to the next step.

|

||

|

11

|

PURPOSE: VERIFY IF FOREIGN MATTER ON INTAKE CMP SENSOR DETECTION AREA AFFECTS DIAGNOSTIC RESULTS

• Visually inspect for intake CMP sensor.

• Is there foreign matter such as metallic dust on the intake CMP sensor detection area?

|

Yes

|

Remove the foreign matter, then go to Step 13.

|

|

No

|

Go to the next step.

|

||

|

12

|

PURPOSE: VERIFY IF FOREIGN MATTER ON CKP SENSOR DETECTION AREA AFFECTS DIAGNOSTIC RESULTS

• Visually inspect for CKP sensor.

• Is there foreign matter such as metallic dust on the CKP sensor detection area?

|

Yes

|

Remove the foreign matter, then go to the next step.

|

|

No

|

Go to the next step.

|

||

|

13

|

PURPOSE: VERIFICATION OF VEHICLE REPAIR COMPLETION

• Always reconnect all disconnected connectors.

• Clear the DTC from the PCM memory using the M-MDS.

• Implement the repeatability verification procedure.

• Perform the DTC Reading Procedure.

• Is the DTC P0011:00 or P0012:00 also present?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM.

Go to the next step.

|

|

No

|

Go to the next step.

|

||

|

14

|

PURPOSE: VERIFY IF THERE IS ANY OTHER MALFUNCTION

• Is any other DTC or pending code stored?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

DTC troubleshooting completed.

|

Details On DTCs (SKYACTIV-G 1.3, SKYACTIV-G 1.5 (with 4-1 exhaust system))

|

DESCRIPTION |

Hydraulic variable valve timing control system: • P0011:00: Over-advanced

• P0012:00: Over-retarded

|

|

|---|---|---|

|

DETECTION CONDITION

|

Determination conditions

|

• P0011:00: A condition in which the actual intake valve timing advances (excess advance) compared to the target intake valve timing continues for the specified period.

|

|

• P0012:00: A condition in which the actual intake valve timing retards (excess retard) compared to the target intake valve timing continues for the specified period.

|

||

|

Preconditions

|

• Battery voltage: above 11 V*1

• Engine speed: 5,000 rpm or less*1

• Engine coolant temperature: 60 °C {140 °F} or more*1

• Hydraulic variable valve timing control: feedback mode

• The following DTCs are not detected:

*1: Value can be verified by displaying PIDs using M-MDS

|

|

|

Malfunction determination period

|

• 5 s period

|

|

|

Drive cycle

|

• 1

|

|

|

Self test type

|

• CMDTC self test

|

|

|

Sensor used

|

• CKP sensor

• Intake CMP sensor

|

|

|

FAIL-SAFE FUNCTION

|

• Not applicable

|

|

|

VEHICLE STATUS WHEN DTCs ARE OUTPUT

|

• Illuminates check engine light.

|

|

|

POSSIBLE CAUSE

|

• OCV malfunction

• Hydraulic variable valve timing actuator malfunction

• Timing chain malfunction

• Mis-detection of intake CMP sensor

• Mis-detection of CKP sensor

• Engine oil malfunction

• PCM malfunction

|

|

System Wiring Diagram (SKYACTIV-G 1.3, SKYACTIV-G 1.5 (with 4-1 exhaust system))

Function Explanation (DTC Detection Outline) (SKYACTIV-G 1.3, SKYACTIV-G 1.5 (with 4-1 exhaust system))

am2zzw00010494

|

am2zzw00010495

|

Repeatability Verification Procedure (SKYACTIV-G 1.3, SKYACTIV-G 1.5 (with 4-1 exhaust system))

PID Item Used In Diagnosis (SKYACTIV-G 1.3, SKYACTIV-G 1.5 (with 4-1 exhaust system))

PID/DATA monitor item table

|

Item |

Definition |

Unit |

Condition/Specification |

|---|---|---|---|

|

VT_EX_ACT

|

• Actual intake variable valve timing control - Advance amount from max retard position

|

°

|

• Displays actual intake variable valve timing - advance amount from max retard position

Idle (after warm up)

Racing (engine speed is 2,000 rpm)

|

|

VT_EX_DES

|

• Target intake variable valve timing control - Advance amount from max retard position

|

°

|

• Displays target intake variable valve timing - advance amount from max retard position

Idle (after warm up)

Racing (engine speed is 2,000 rpm)

|

Function Inspection Using M-MDS (SKYACTIV-G 1.3, SKYACTIV-G 1.5 (with 4-1 exhaust system))

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

PURPOSE: VERIFY RELATED SERVICE INFORMATION AVAILABILITY

• Verify related Service Information availability.

• Is any related Service Information available?

|

Yes

|

Perform repair or diagnosis according to the available Service Information.

• If the vehicle is not repaired, go to the next step.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: RECORD VEHICLE STATUS AT TIME OF DTC DETECTION TO UTILIZE WITH REPEATABILITY VERIFICATION

• Record the FREEZE FRAME DATA/snapshot data on the repair order.

|

—

|

Go to the next step.

|

|

3

|

PURPOSE: VERIFY IF DIAGNOSTIC RESULT IS AFFECTED BY OTHER RELATED DTCs OCCURRING

• Switch the ignition off, then ON (engine off).

• Perform the Pending Trouble Code Access Procedure and DTC Reading Procedure.

• Is the PENDING CODE/DTC P0335:00, P0340:00, P2088:00 or P2089:00 also present?

|

Yes

|

Go to the applicable PENDING CODE or DTC inspection.

Go to the next step.

|

|

No

|

Go to the next step.

|

||

|

4

|

PURPOSE: VERIFY CONFORMITY OF ACTUAL INTAKE VALVE TIMING AND DETERMINE IF MALFUNCTION IS CAUSED BY OCV OR CONNECTOR RELATED

• Start the engine and idle it.

• Access the following PIDs using the M-MDS:

• Perform the following:

• Does the monitor value of the PID item VT_EX_ACT conform to the VT_EX_DES PID value?

|

Yes

|

Go to the next step.

|

|

No

|

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

||

|

5

|

PURPOSE: VERIFY CONNECTOR CONNECTIONS

• Start the engine.

• Access the VT_EX_ACT PID using the M-MDS.

• Does the PID value fluctuate when the following connectors are shaken?

|

Yes

|

Repair or replace the applicable wiring harness or connector parts.

Go to the troubleshooting procedure to perform the procedure from Step 8.

|

|

No

|

Go to the troubleshooting procedure to perform the procedure from Step 1.

|

Troubleshooting Diagnostic Procedure (SKYACTIV-G 1.3, SKYACTIV-G 1.5 (with 4-1 exhaust system))

|

STEP |

INSPECTION |

RESULTS |

ACTION |

|---|---|---|---|

|

1

|

PURPOSE: DETERMINE INTEGRITY OF HYDRAULIC VARIABLE VALVE TIMING ACTUATOR

• Inspect the hydraulic variable valve timing actuator.

• Is there any malfunction?

|

Yes

|

Replace the hydraulic variable valve timing actuator, then go to Step 8.

|

|

No

|

Go to the next step.

|

||

|

2

|

PURPOSE: VERIFY ASSEMBLY CONDITION OF TIMING CHAIN

• Verify the condition of the timing chain assembly (intake valve timing, looseness, jumping).

• Is there any malfunction?

|

Yes

|

Repair or replace the malfunctioning part.

Assemble the timing chain using the correct timing, then go to Step 8.

|

|

No

|

Go to the next step.

|

||

|

3

|

PURPOSE: VERIFY IF FOREIGN MATTER ON INTAKE CMP SENSOR DETECTION AREA AFFECTS DIAGNOSTIC RESULTS

• Visually inspect for intake CMP sensor.

• Is there foreign matter such as metallic dust on the intake CMP sensor detection area?

|

Yes

|

Remove the foreign matter, then go to Step 8.

|

|

No

|

Go to the next step.

|

||

|

4

|

PURPOSE: INSPECT IF INSUFFICIENT HYDRAULIC PRESSURE CAUSED BY USE OF UNSPECIFIED ENGINE OIL

• Is the specified engine oil being used?

|

Yes

|

Go to the next step.

|

|

No

|

Replace the engine oil with genuine motor oil, then go to Step 8.

|

||

|

5

|

PURPOSE: INSPECT ENGINE OIL LEVEL

• Inspect the engine oil level.

• Is the engine oil level sufficient?

|

Yes

|

Go to the next step.

|

|

No

|

Add genuine motor oil, then go to Step 8.

|

||

|

6

|

PURPOSE: INSPECT ENGINE OIL PRESSURE

• Inspect the engine oil pressure.

• Is there any malfunction?

|

Yes

|

Go to the next step.

|

|

No

|

Go to Step 8.

|

||

|

7

|

PURPOSE: VERIFY IF MALFUNCTION RELATED TO ENGINE OIL LEAK OR RESTRICTION AFFECTS DIAGNOSTIC RESULTS

• Start the engine.

• Verify if there is engine oil leakage in the oil passage or restriction.

• Is there engine oil leakage in the oil passage or restriction?

|

Yes

|

Repair or replace the malfunctioning part according to the inspection results.

Add genuine motor oil, then go to the next step.

|

|

No

|

Go to the next step.

|

||

|

8

|

PURPOSE: VERIFICATION OF VEHICLE REPAIR COMPLETION

• Always reconnect all disconnected connectors.

• Clear the DTC from the PCM memory using the M-MDS.

• Implement the repeatability verification procedure.

• Perform the Pending Trouble Code Access Procedure.

• Is the DTC P0011:00 or P0012:00 also present?

|

Yes

|

Repeat the inspection from Step 1.

• If the malfunction recurs, replace the PCM.

Go to the next step.

|

|

No

|

Go to the next step.

|

||

|

9

|

PURPOSE: VERIFY IF THERE IS ANY OTHER MALFUNCTION

• Is any other DTC or pending code stored?

|

Yes

|

Go to the applicable DTC inspection.

|

|

No

|

DTC troubleshooting completed.

|